IR Thermography for QA and Product Safety in Cooked and Frozen Food Field

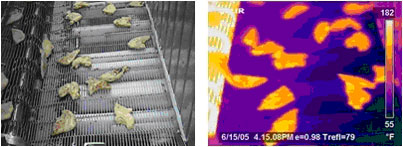

IR thermography is first and foremost a quality assurance (QA) tool. Controlling the quality and safety of cooked and frozen meat products is an excellent use of this technology. A permanently mounted IR camera can record the temperature of, for example, chicken tenders as they exit a continuous conveyor oven (Figure 2). The objective is to make sure they are done enough (reach the right temperature), but not over-cooked and dried out.

Digital photo (left) and IR thermogram (right) of a chicken tender oven conveyor line.

Note the temperature scale in the thermogram of Figure 2. It shows that the chicken tenders just exiting the oven are at a temperature of about 150°F. (Camera firmware allows the creation of temperature scales with more intermediate divisions if desired.) Temperatures below 140°F pose safety risks from e-Coli and other harmful bacteria that may not have been killed. While higher temperatures provide a margin of safety, going above 170°F can dry out the product, degrading its texture, aroma, and taste. Reduced moisture content also represents yield loss on a weight basis.

Considerable research has been conducted to correlate surface temperatures obtained through thermographic measurements with product core temperatures taken with thermocouples or other contact sensors [1]. For example, a Georgia Tech Research Institute (GTRI) Agricultural Technology Research Program study [2] found that the core temperature relative to the surface temperature of cooked chicken products depends on a number of factors. These include whether or not the chicken pieces have been breaded, how heavy that coating is, and whether the coating has been ruptured.

In addition, there is the possibility that some of the pieces may have been colder than others when they went into the oven, or may have gotten partially covered by another piece during handling or on the conveyor. In any case, pieces that come out of the oven with a temperature below or above the levels set in IR camera firmware will cause an alarm output to be triggered. This will also show up on a video or PC monitor so an operator can remove bad pieces from the conveyor.

From single machines to complete processing lines,we enhance value and

capture quality, nutrition and taste in food products. 2012 All right reserved.

Technical Support:lanhaiit.com